how to start

The information included in this research is regional, as all sustainability research tends to be. To start your own research on the materials you receive for your studio, follow these steps as a guideline. This is the process that I’ve found most successful. Please feel free to reach out to me with your findings, questions, or tips you have!

doing your own research:

Start with your local distributor. Who does your distributor purchase clay materials from? Where do they get their materials? This will set up your consistent traceable miles–the distance your materials always travel, no matter where they come from.

Each clay distributor is required to have MSDS (Material Safety Data Sheets) for each material. This sheet will give you information about toxicity, airborne particulate risks, and the supplier from which the material comes from. The SDS will (most likely) give you a physical address for the headquarters of the operation. Use this to verify the company website after a Google search.

From here, dig around on their website. Sometimes, companies will have a “locations” tab, giving exact addresses of the mines, some will simply give cities. Other companies bury this information, so downloading and reading through their stakeholder report or annual sustainability report is the next best option. This is a lot of work, but generally results in more information for companies that bury the lead. You can attempt to call the company and ask where their mines are located, but this is often proprietary information that they refuse to share to a stranger on the phone.

It can also be effective to simply Google the company’s name and “mine locations.” If all of these steps fail, try to look up EPA documents that give locations of materials mines and cross reference them with the company. If you must use this tactic, you will find that many mines have names that are similar to the company, but not exact.

Google news reports that relate to the company–you will often find fines that have been issued or lawsuits that the company has been in. This will give you an idea of their sustainability initiatives. You can also read their sustainability reports and projections, but keep in mind that these companies often try to stretch the truth, or outright lie.

Distribution of product is a whole other beast to tackle. Companies will always take the most profitable route to distribute their product. Take care to notice the plants and how they are titled. Sometimes companies distribute straight from their refinery–others have “distributing plants” or “packing plants” that the material travels to before heading to your local distributor.

In the United States, you can safely bet that between plants or distributing locations, the company is using the quickest route for their product. This often means major interstates and highways. Punch in the route on Google Maps and record the mileage between each location to get your final number.

The EPA will provide lots of information on the way clay materials are mined and processed. Consult their PDFs to discover further information about the way the materials are generally processed in the United States. They will also give you a little information on the sustainability of those practices.

bentonite: an example

My studio is in Missoula, Montana. I drive to purchase my materials from Archie Bray Clay in Helena, Montana, and ABC purchases materials from Laguna Clay Company in City of Industry, California. This is the consistent route that all of my materials take after being mined, refined, and distributed.

ABC’s bentonite comes from The American Colloid Company, whose headquarters are located in Hoffman Estates, Illinois. Their website is also listed on the SDS. A quick search of their website will actually take you to Minerals Technologies’ website, their parent company. This is very common in researching and can make finding the information you are looking for even more difficult.

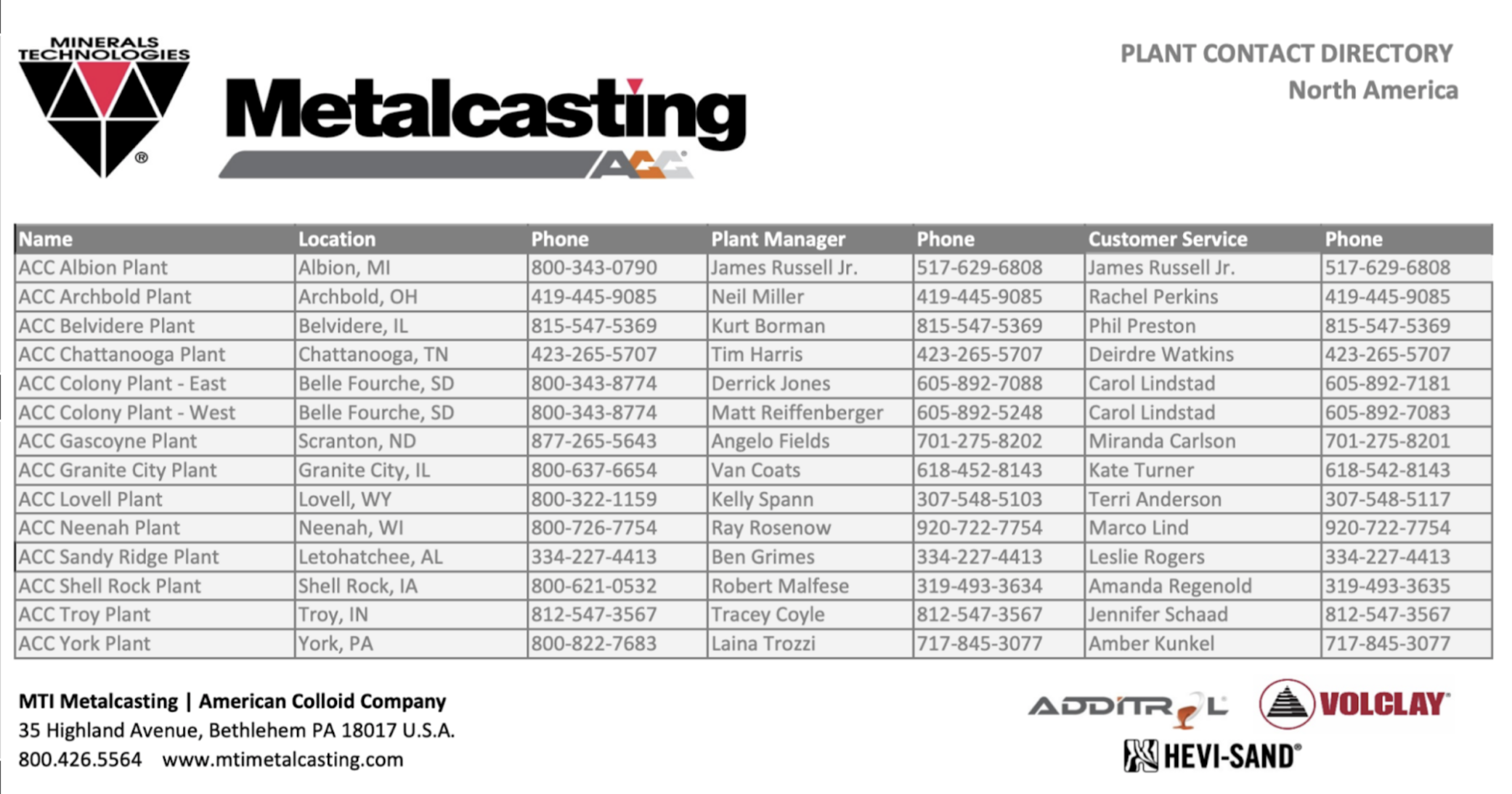

After digging around for a bit on their website, I located a “Plant Contact Directory” which outlined each plant location. Googling and Google mapping eventually led me to identify which plants were mines and which were refineries/packing plants. In the vast majority, American clay mines use the open pit mining method, which means the mines are very obvious from satellite photos.

In the case of The American Colloid Company bentonite mines, they disclose the fact that they have plants all over the world, but much of their bentonite comes from Wyoming. They give the locations for one mine in Wyoming, however, a Google Maps search comes up with a second undisclosed mine in Wyoming, credited to the company “American Colloid” as opposed to “The American Colloid Company.”

**Keep in mind that this is a parent company. The mines listed in their plant directory could be administrative offices, refineries, or mines for other materials. Ensure that the mines you are looking at are actually mines, and that they are mining the correct material.

Consulting the EPA’s AP-42 CH 11.25: Clay Processing document gave me the information I was looking for regarding the process of bentonite mining and refining.